Fit To Your Needs

Custom Identification Systems

Verilogic has over twenty years of experience implementing custom identification solutions in manufacturing environments. From simple Print and Scan Systems to RFID systems to Vision based systems reading infrared ink marks, we can develop a system to meet your business needs.

Label, scan and verify products regardless of their shape or size!

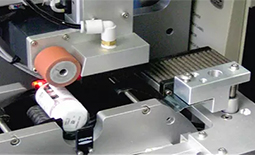

Vial Labeling & Vision Verification

Vial Labeling & Vision Verification

- Integration can be semi-automatic with manual product load or fully automated

- Vial handling controlled within a Star Wheel assembly

- Application controlled through a Wrap Wheel

- High resolution vision systems are capable of reading image and data, including 1D & 2D barcodes

Parts Kitting Operation

-

- Multiple build stations with HMI Terminals, Scales and Hand Scanners

- Station activity reported back to main PC to view real time data

- Interface screen can be integrated in different languages to accommodate production outside the US

2D Code Vision Inspection

2D Code Vision Inspection

-

- System includes PC, Cognex vision camera

- Processes at speeds up to 200 parts per minute

- Complete controls for recording and verifying 2D Data Matrix code, laser marked on plastic housing

Stand Alone Printing & Verification

-

- System includes PC, Zebra Printer and hand scanner

- Print customer specific labels on demand

- Labels are verified and reported to WMS in real time

Paper Ream Verification

Paper Ream Verification

-

- System includes custom manufactured adjustable fixture with sensor array, Cognex vision, Allen Bradley HMI and discrete interface

- Provide verification to ensure correct label is on the correct ream

- Confirm ream dimensions are within specified tolerance

Soup Can Label Verification

Soup Can Label Verification

-

- System includes Cognex vision, custom conveyor for product control and high speed reject device

- Cognex camera for full 360 degree inspection and verification of the UPC

- Processes at speeds up to 300 cans per minute

Furnace Panel Labeling

- Ergonomic system for consistent placement of labels on furnace panels

- Custom fixture enables automatic printing and application

Return Product Inspection & Recording

-

- System reads RFID tags and weighs each product

- Data is recorded to a central database

- Trends can be established based upon data capture of defective product by lot

Yarn Perth Labeling & Verification

Yarn Perth Labeling & Verification

-

- System automatically print and apply labels to the core of a yarn roll

- Custom label applicator that utilizes x/y/z axis

- Barcode scanner for label verification and custom software

Pool Heater Identification System

- On demand printing of product labels and schematics at multiple stations in the manufacturing process

- System includes HMI, Zebra printer and hand scanners at each station

- Devices report back to main PC

Small Carton Marking with Inkjet

- Originally generated for small boxes of automotive parts

- Select the order and part number to generate the print data for the individual box